Vacuum pump oil may seem like such a minor detail in the context of a larger-than-life, powerful Allvac® vacuum tanker – but it can make all the difference to the running of a specialist vehicle like this.

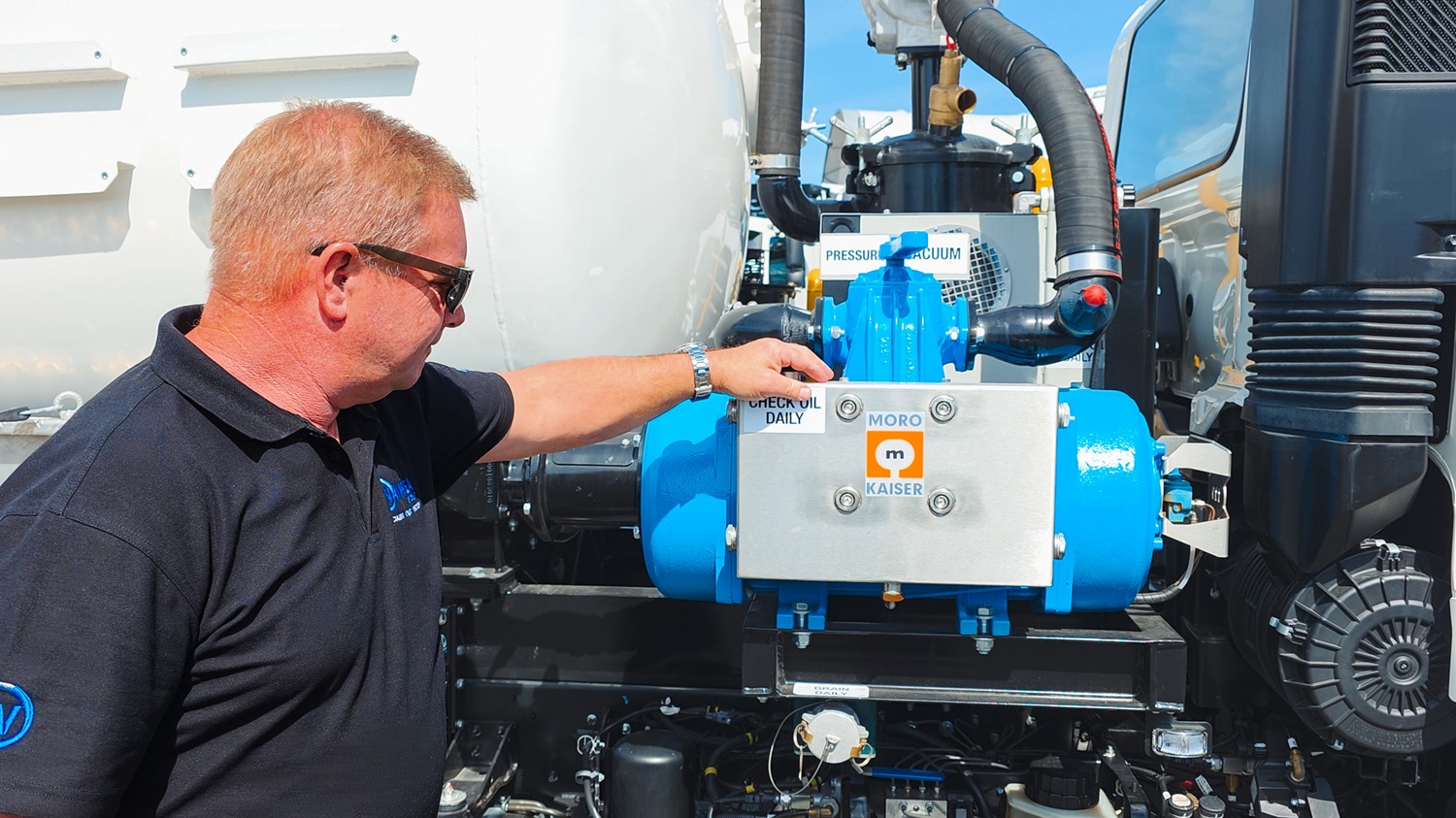

Waimea Group’s specialist vacuum tankers run on the Italian-made Moro Kaiser pump – in the video below you’ll see two sporting the Moro Kaiser PM90T, a powerhouse of a vacuum pump. It has 6 vanes and can run from 1000 up to 1300 rpm. This is a top-of-the-line piece of equipment, and the results show its worth!

The Moro Kaiser is different from a lot of older model rotary vane pumps – it’s very efficient with its oil. Some pumps will churn through the oil, which causes potential stress and damage to the pump, a lot of annoying refilling for operators, and expenses building up. Waimea’s Allvac® vacuum trucks are able to avoid most of these issues with their oil-efficient pumps, saving time, stress, and money for their owners. However, even with a powerful piece of equipment like this in your truck, it can still get damaged if you’re not aware about the type of oil you should be using.

Vacuum pump oil works by pulling through the pump while it’s operating and keeping the bore at the back lubricated while the vanes run around it, so that it can continue to run smoothly. That’s why it’s important to use the best quality oil in your pump.

Sealing: The vacuum pump oil acts as a sealing fluid. It fills the microscopic gaps and clearances between the moving parts internally (like the rotor and vanes in a rotary vane pump) to create the necessary seal. This seal is crucial for maintaining the deep vacuum pressure that the pump is designed to achieve.

Lubrication: The oil lubricates the internal components, reducing friction and wear between the moving metal parts. This extends the lifespan of the pump and helps ensure smooth, efficient operation.

Cooling: The oil absorbs and transfers heat generated by the pump's mechanical action and gas compression, carrying it away from the hot spots to the pump casing where it can be dissipated.

So now understanding why vacuum pump oil is so important for the operation of your equipment, which oil should you use? Moro Kaiser recommend an ISO 100 grade oil for their vacuum pumps, which has a very high viscosity, or thickness. Some operators will use a 46 or 68 grade oil, and that may be cheaper, but it can potentially damage the vacuum pump. Thinner oils like these have a lower flash point and can smoke off under the 100 degree temperatures inside a pump pulling high vacuum. This causes white smoke from the exhaust due to the evaporation within the pump, and the oil will be burned off and leave the pump running dry, causing premature wear to the vanes and bore.

Three things will damage your vacuum pump without proper care: dirty air, which can be fixed with a diesel flush as shown in a previous video; wrong rpm for your pump; and heat from using the wrong oil. This is what you can prevent. At Waimea we supply the ISO 100 grade oil recommended by Moro Kaiser, which will keep your pump running smoothly.

Not only does it help your pump - it also smells good. This might sound like a ludicrous, pointless detail, but for liquid waste operators emptying a grease trap or dealing with other, distinctly un-fragrant liquid waste, this scented oil is a real benefit to your nose, as well as your pump.

Better smells, smoother running, and efficient operation – don’t underestimate how using the right vacuum pump oil in an Allvac® can take your liquid waste work to the next level!

Watch this video below to learn more: