As a lineworker, your focus is naturally trained on what’s above: the lines, the connections, and any problems that need fixing. But when you're setting up an Elevating Work Platform (EWP), the ground beneath your equipment is just as critical as the hardware over your head. Safety starts long before you leave the ground.

Working on power lines usually involves the use of a lines crane or bucket truck (EWP) that utilises outriggers for stability. When those outriggers are deployed, the entire weight of that multi-ton truck is transferred straight into the ground at those four contact points. In order to keep that from creating an imbalance, trucks are programmed with HSPC and use stabiliser pads beneath the outriggers – but that’s not enough if the ground itself is unstable and unable to bear the load.

Different environments present unique challenges for line crane trucks and EWPs. Some types of ground surface can be volatile and not up to the weight of a truck bearing down on it. In these cases, the point where all the weight is focused – the outrigger – can punch through the surface, immediately causing a whole array of issues, from an unstable truck to risk to operators to damaged infrastructure.

This can happen in a variety of environments. In urbans settings, the primary risk is lack of structural support beneath pavement and other infrastructure. If an outrigger punches through unsupported concrete, it can disrupt and damage water and electrical services, overbalancing your truck and putting your crew and pedestrians at risk.

The risk is no less when working in rural areas – rural ground is far more unpredictable and can lead to disaster. Boggy areas, loose sandy ground, hidden pockets or waterways, or old, forgotten services can all lie just out of sight beneath the service, leading to major issues when you attempt to deploy your outriggers.

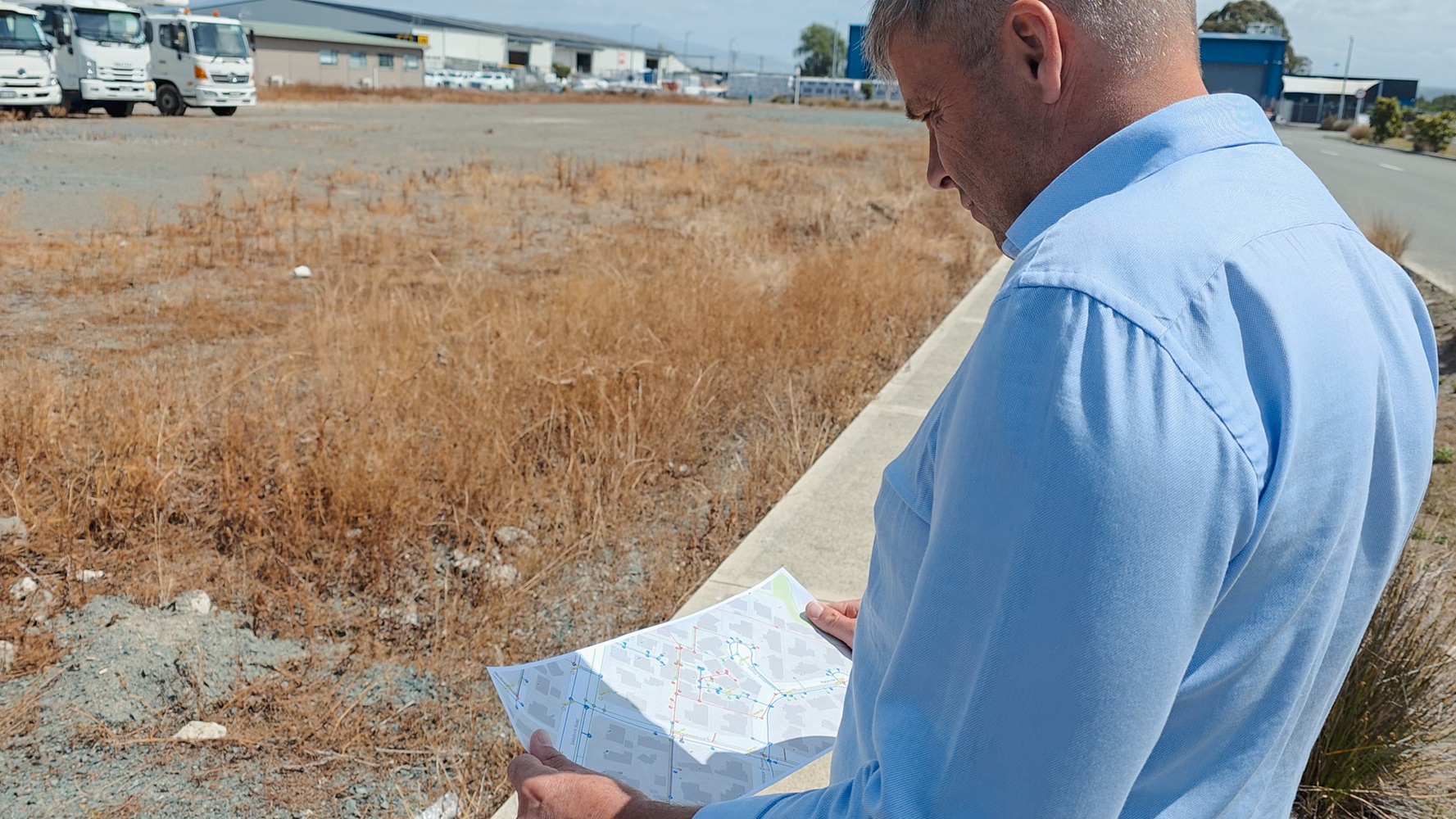

The key to preventing accidents is a thorough pre-site inspection. Before deploying your outriggers, so you can identify the hazards at your worksite.

The principle resource you need are service plans – these will show you where waterways, drains, and electrical cables lie beneath the surface where you’re working, and what weaknesses and danger zones you need to avoid. Once you know this, you can take preventative measures.

First, identify the hazards at your worksite. If the ground is unsafe, reposition your truck – or alternatively, you can short-jack, provided you do it with care. For more information on how Waimea’s Linelift® units are set up for safe short-jacking, check out this video . You can also use interlocking stabiliser pads and wedges to keep your truck properly balanced. As mentioned, a stabiliser pad regulates the weight on the ground from the outrigger and keeps uneven ground from causing problems with balance. This can be combined with a wedge when on slopes or other irregularities in the surface, which keeps the truck level and prevents it from tipping over.

When working at height, your focus on the lines above should never distract you from the ground beneath. Ensuring your line crane truck or bucket truck is properly supported is the most important step in every job. Check out this video to learn more.